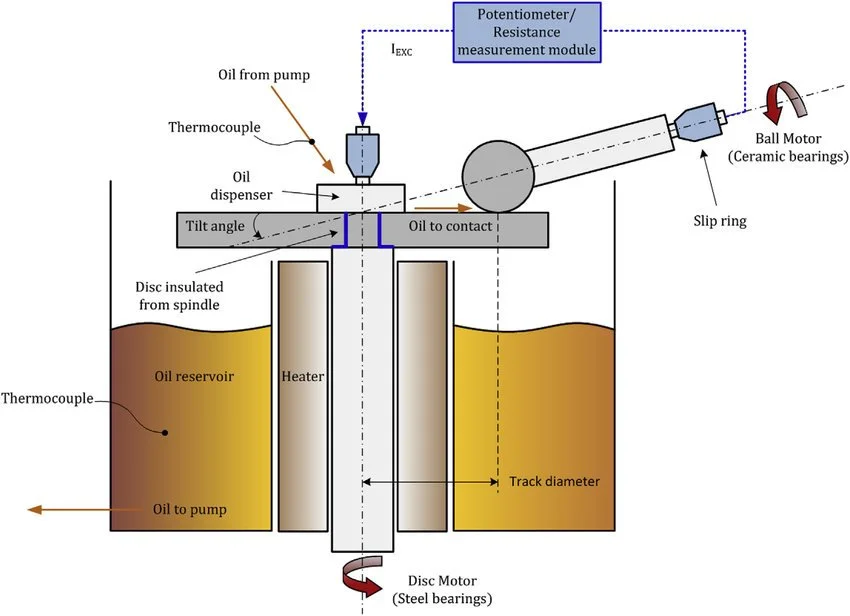

During my Internship at Wright-Patterson Air Force Base, I worked as a tribology intern during the summer of 2023. I was looking at the ball bearing interactions inside jet propulsion systems. To do so I learned how to use WAM Machine which is ball on disc test machine capable of evaluating wear, scuffing, and fatigue resistance capabilities with ball and disc test specimens. I was charged with helping research how different lubricants affected the wear behavior of bearings operating under extreme load and temperature conditions. The goal of my experimentation was to evaluate which lubricant composition offered the best surface protection and service life without compromising efficiency. Working alongside a mentor, I helped run the machine and record the results of each test to make an overall judgment. When it came to the different oils, the main things we were tracking were the friction coefficients in real time, the amount of material loss on the disc along with material growth, the uniformity of the surface, and the amount of temperature each oil could withstand. Using high performance, both optical and electron microscopy devices, I worked to quantify our variables into an optimal choice for long duration aerospace applications over multiple data sets and weeks of testing.